Mining

AI Applications – Mining Centers

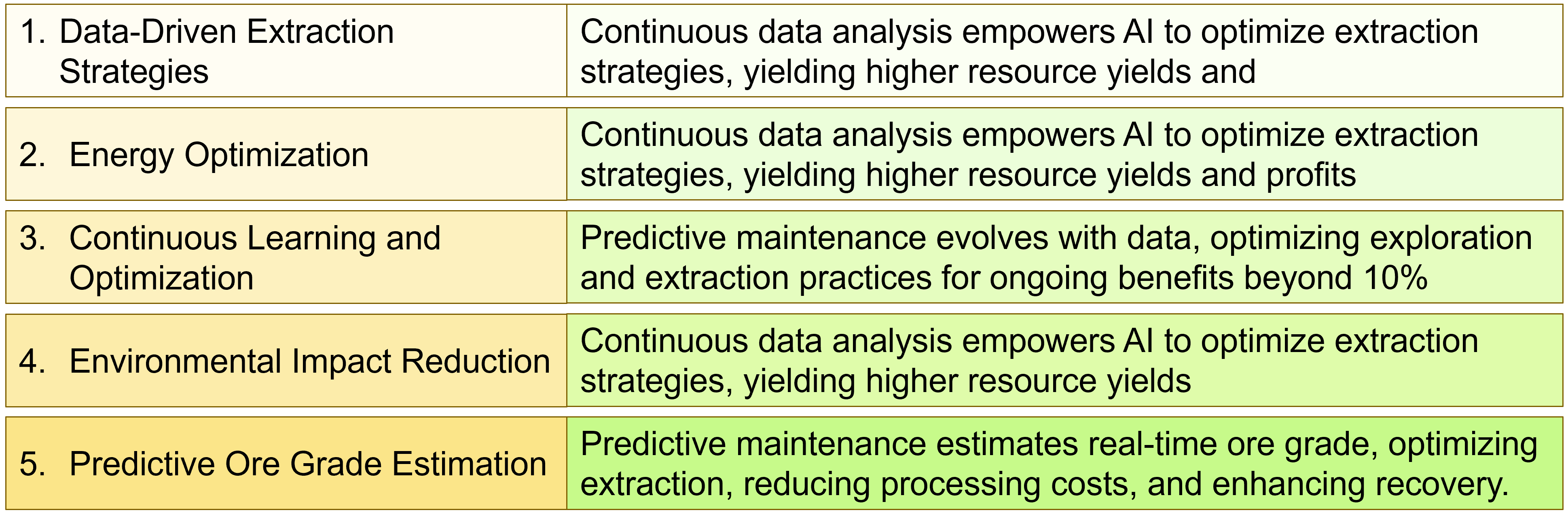

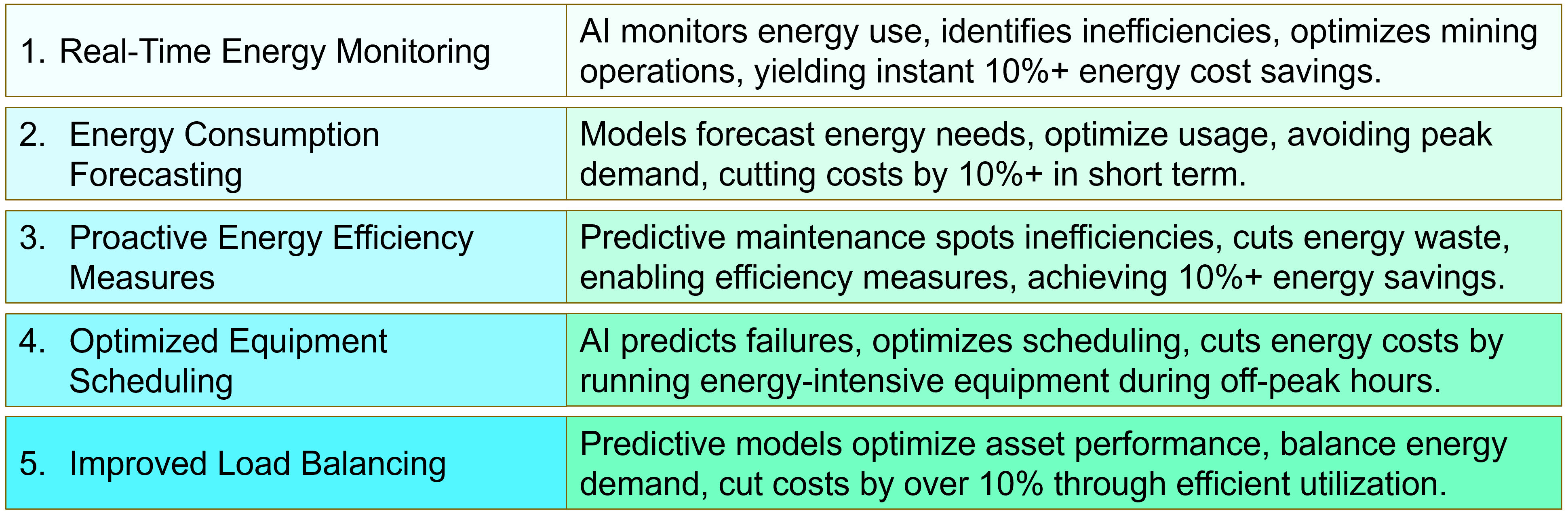

Energy Optimization in Mining Operations Short Term Benefits

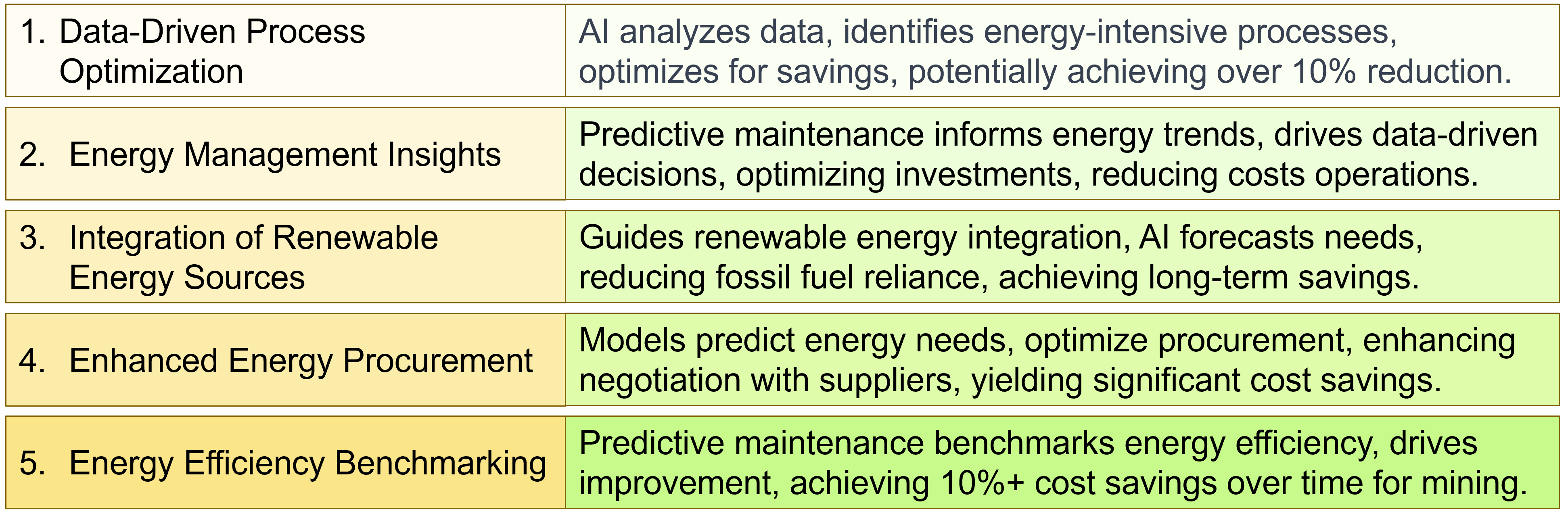

Energy Optimization in Mining Operations Medium Term Benefits

Inventory Management for Mining Operations Short Term Benefits

Inventory Management for Mining Operations Medium Term Benefits

Resource Exploration and Extraction Short Term Benefits

Resource Exploration and Extraction Medium Term Benefits

Ore Grade Prediction Short Term Benefits

Ore Grade Prediction Medium Term Benefits

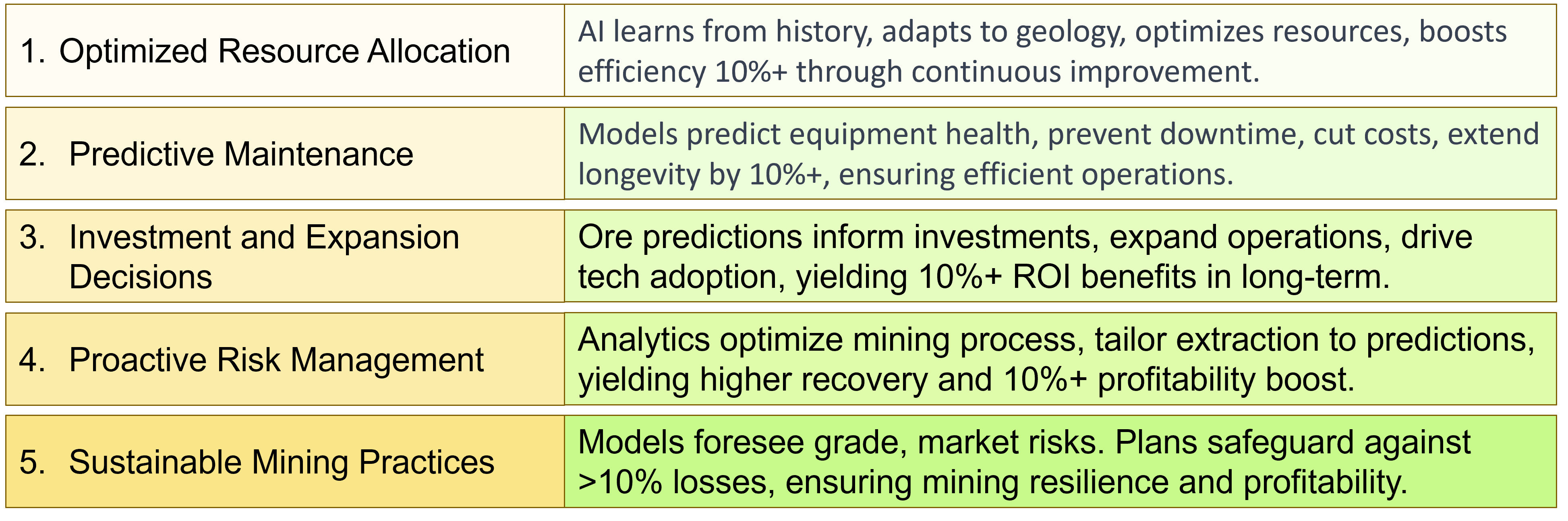

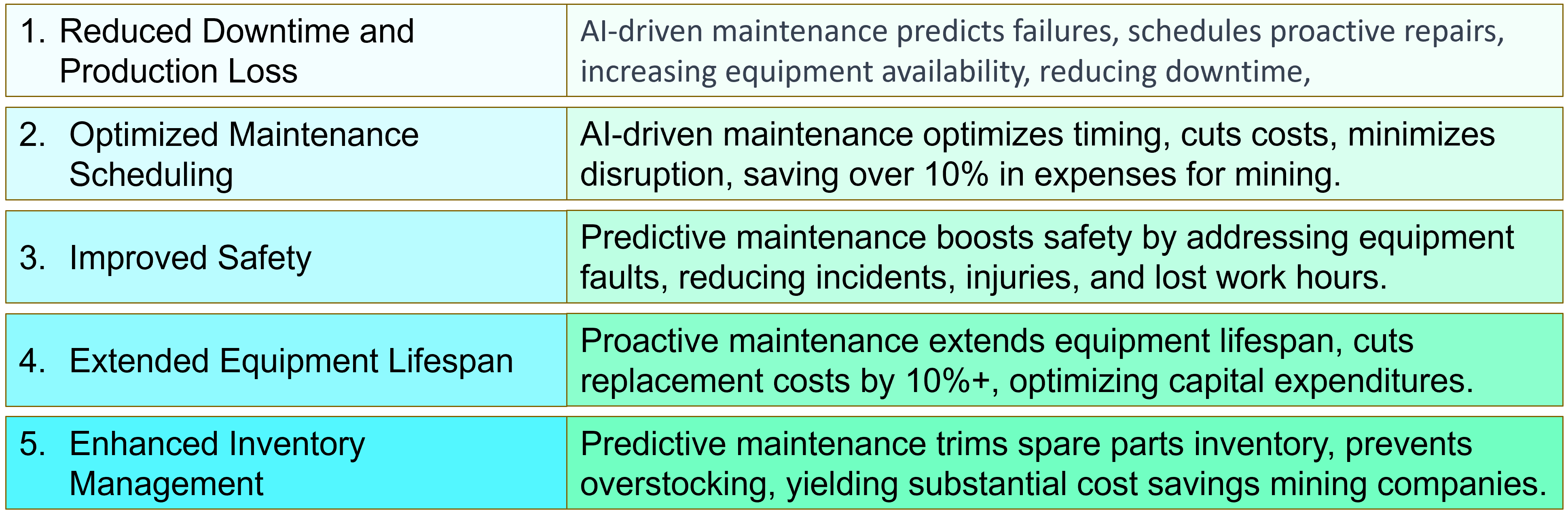

Predictive Maintenance for Mining Equipment Short Term Benefits

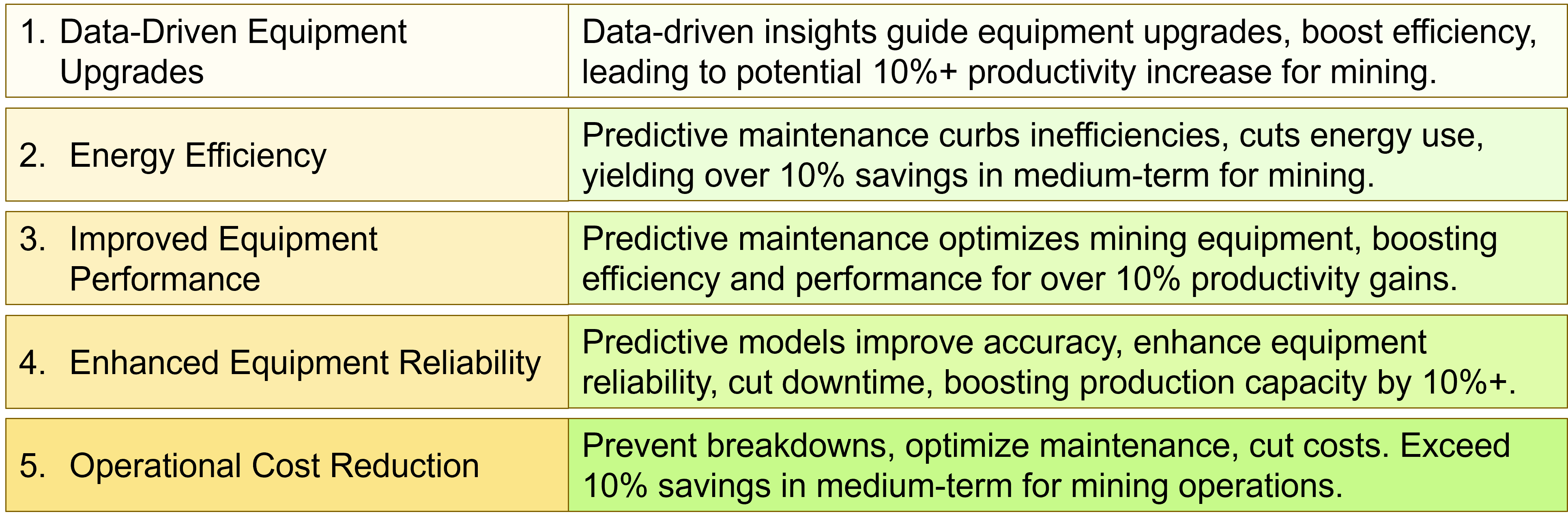

Predictive Maintenance for Mining Equipment Medium Term Benefits

AI Applications – Mining Centers

*Note: SPCC Toquepala Open Pit - Peru

Application of AI, machine learning, and predictive analytics in mining centers offers significant short-and medium-term benefits, including improved ore grade prediction, predictive maintenance, energy optimization, efficient inventory management, and enhanced resource exploration. These technologies enable smarter decision-making, reduced costs, increased productivity, and more sustainable mining practices, all of which can exceed the 10% threshold for short- and medium-term benefits.

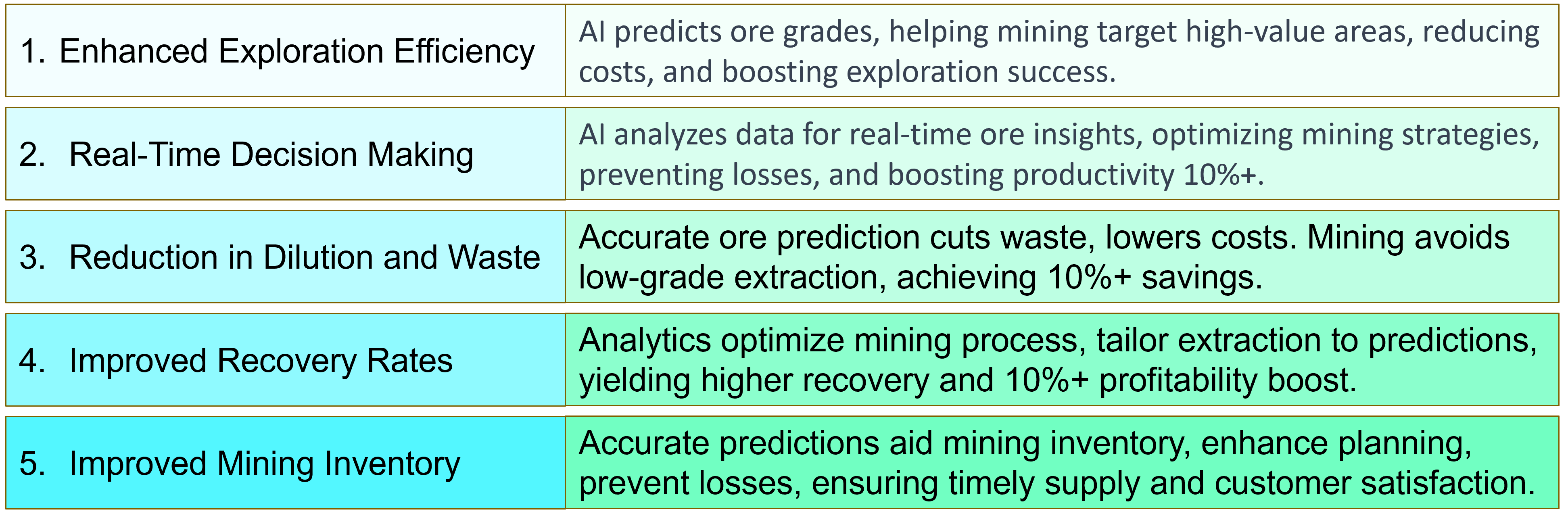

Ore Grade Prediction Short Term Benefits

AI and machine learning algorithms can be applied to analyze geological data, drilling results, and historical production data to predict the copper ore grade in different mining areas. By accurately estimating the ore grade before extraction, mining operations can focus on higher-grade areas, maximizing the yield of copper per ton of ore.

Ore Grade Prediction Medium Term Benefits

By leveraging AI and machine learning, mining companies optimize resource allocation, prevent downtime, make informed investments, manage risks, enhance sustainability, and gain competitive advantage, potentially increasing efficiency, longevity, returns, and market share by over 10%.

Predictive Maintenance Short Term Benefits

AI-powered predictive maintenance monitors essential mining equipment like trucks, excavators, and crushers, analyzing sensor data (temperature, vibration, usage) to forecast potential failures. This enables proactive scheduling of repairs and replacements by maintenance teams, resulting in minimized downtime, optimized maintenance, heightened safety, prolonged equipment longevity, improved inventory management, and elevated productivity.

Predictive Maintenance Medium Term Benefits

Incorporating data-driven equipment upgrades, energy efficiency, enhanced reliability, cost reduction, predictive maintenance services, and improved performance enables mining companies to achieve holistic gains of over 10% in productivity, revenue, and operational efficiency.

Energy Optimization in Mining Operations Short Term Benefits

AI-powered predictive maintenance monitors essential mining equipment like trucks, excavators, and crushers, analyzing sensor data (temperature, vibration, usage) to forecast potential failures. This enables proactive scheduling of repairs and replacements by maintenance teams, resulting in minimized downtime, optimized maintenance, heightened safety, prolonged equipment longevity, improved inventory management, and elevated productivity.

Energy Optimization in Mining Operations Medium Term Benefits

Continuous data analysis with AI and predictive models optimizes energy-intensive processes, reduces energy costs by 10%, supports renewable integration, enhances procurement, upgrades equipment, and benchmarks energy efficiency for mining companies.

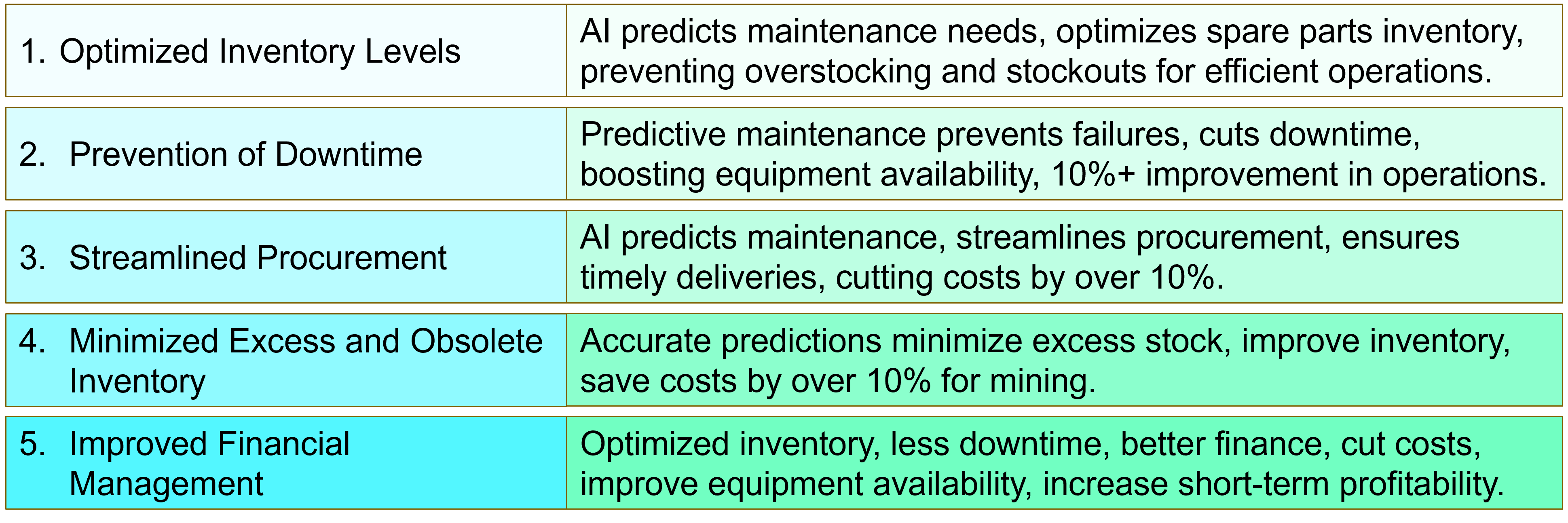

Inventory Management for Mining Operations Short Term Benefits

By integrating AI, machine learning, and predictive analytics into inventory management for mining, short- and medium-term advantages emerge. These encompass optimized inventory levels, curbed downtime, efficient procurement processes, reduced obsolete inventory, enhanced financial oversight, and scalability potential.

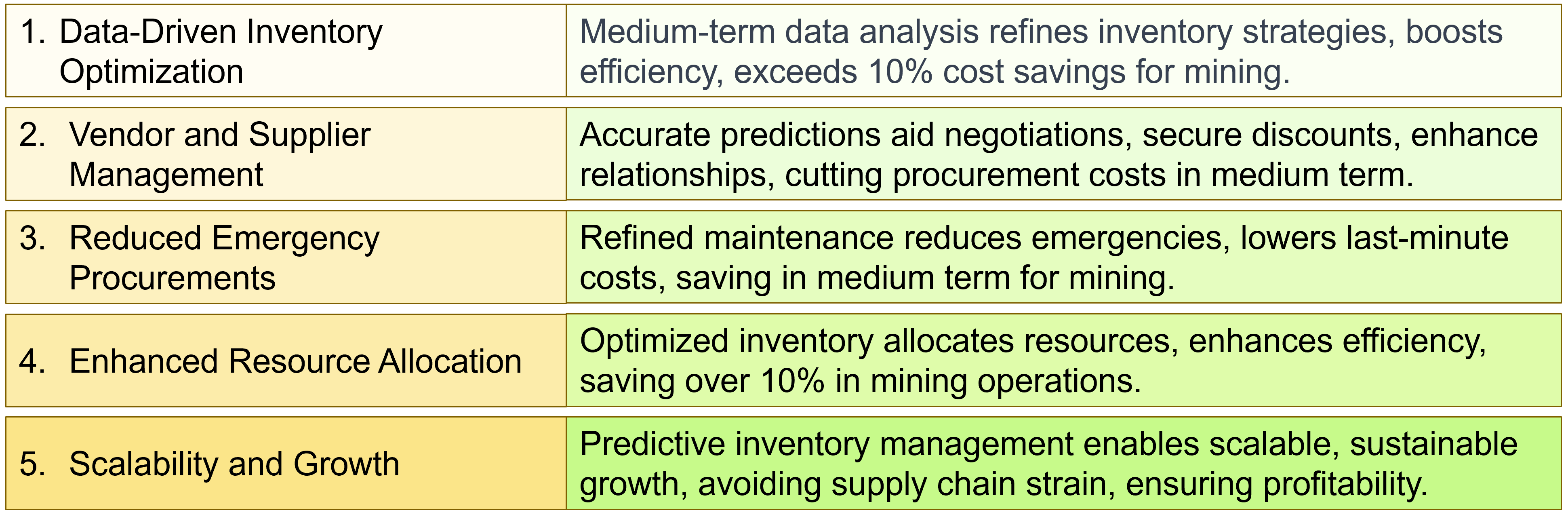

Inventory Management for Mining Operations Medium Term Benefits

Continuous data analysis enhances inventory optimization, allowing mining companies to refine policies for potential cost savings. Advanced predictive maintenance reduces emergency procurements, lowering last-minute expenses, boosts efficiency and achieves savings. Predictive data-driven maintenance supports scalable, profitable growth and decisions that foster long-term competitiveness.

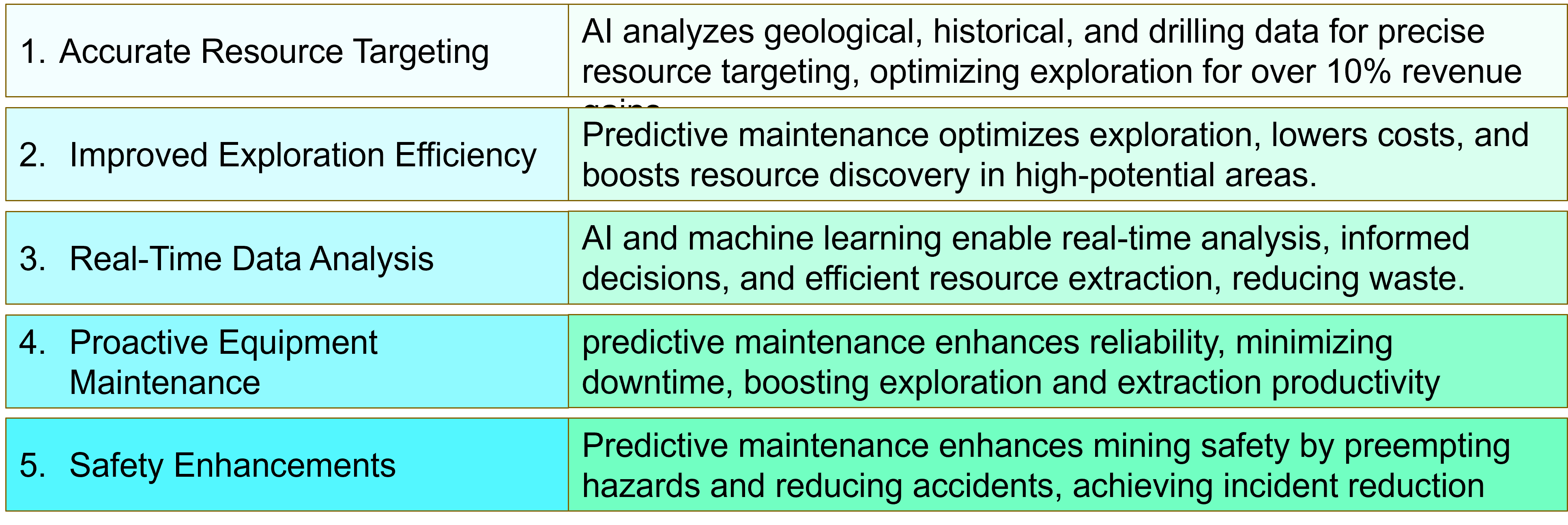

Resource Exploration and Extraction Short Term Benefits

AI and machine learning optimize copper exploration and mining through geological and historical data analysis. Benefits include targeted resource identification, efficient exploration, real-time analysis, equipment maintenance, safety, energy optimization, and environmentally conscious practices for enhanced productivity and sustainable growth.

Resource Exploration and Extraction Medium Term Benefits

AI-driven data analysis refines extraction strategies, optimizes energy usage, tailored equipment upgrades, reduces environmental impact, estimates ore grade, and ensures continuous learning. These data-driven approaches enhance mining efficiency, resource recovery, cost savings, and sustainability, surpassing 10% improvement thresholds.