AI Benefits – Blast and Electric Furnace

*Note: SPCC Toquepala Open Pit - Peru

Application of AI, machine learning, and predictive analytics in blast and electric furnaces can provide significant short- and medium-term benefits, such as reduced downtime, improved energy efficiency, enhanced product quality, streamlined production planning, and cost savings, all of which can exceed the 10% threshold. These technologies enable smarter decision-making, better resource utilization, and a more proactive approach to maintenance and operations, leading to a competitive advantage and long-term sustainability for furnace operators.

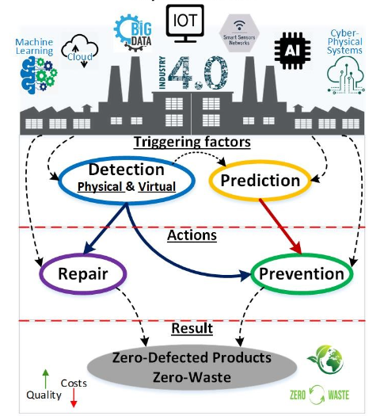

Anomaly Detection and Predictive Maintenance

| AI and machine learning algorithms can be utilized to continuously monitor data from various sensors installed in blast and electric furnaces. These sensors measure parameters like temperature, pressure, gas emissions, and electrical current. By analyzing historical data and identifying patterns, the models can detect anomalies and predict potential equipment failures. | |

| Short-term Benefits | Reduction in unplanned downtime: Early detection of anomalies allows maintenance teams to take proactive measures and avoid unexpected breakdowns, resulting in decreased downtime.

Cost savings: Preventive maintenance and optimized repairs can reduce the need for expensive emergency repairs, leading to significant cost savings. |

| Medium-term Benefits | Extended equipment lifespan: Proactive maintenance and timely repairs can increase the lifespan of furnace components, minimizing the need for frequent replacements and repairs |

Process Optimization

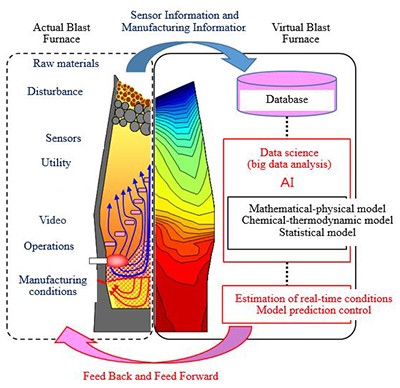

| AI and machine learning can optimize the complex processes involved in blast and electric furnaces, considering factors such as raw material composition, airflow, temperature, and chemical reactions. These models can learn from historical data and recommend the best settings for efficient and productive furnace operations. | |

| Short-term Benefits | Improved energy efficiency: Optimizing furnace operations can lead to reduced energy consumption, resulting in immediate cost savings.

Enhanced product quality: Precise control of the furnace process ensures consistent and high-quality output, reducing waste and rework |

| Medium-term Benefits | Increased productivity: By fine-tuning the furnace processes, productivity can be enhanced, leading to higher output and better resource utilization |

Demand Forecasting and Inventory Management

| AI and predictive analytics can be used to forecast demand for the products produced in blast and electric furnaces. By considering historical production data, market trends, and other relevant factors, the system can optimize inventory management, ensuring the right level of raw materials and finished products are available. | |

| Short-term Benefits | Cost reduction: Optimized inventory levels prevent overstocking and stockouts, reducing carrying costs and waste. Improved supply chain efficiency: Accurate demand forecasting enables better coordination with suppliers, minimizing lead times and potential production delays |

| Medium-term Benefits | Streamlined production planning: Improved demand forecasting allows for better production planning, resulting in smoother operations and resource allocation. |

Quality Control and Defect Detection

| AI and machine learning algorithms can analyze data from sensors and visual inspection systems to monitor product quality in real-time. By comparing product characteristics to established quality standards, the system can identify defects and deviations from specifications. | |

| Short-term Benefits | Reduced waste: Early detection of defects prevents the production of non-conforming products, reducing waste and production costs. Enhanced customer satisfaction: Improved product quality ensures that customers receive products that meet their expectations, leading to higher satisfaction and repeat business |

| Medium-term Benefits | Brand reputation: Consistent high-quality products build a positive brand reputation, leading to increased customer loyalty and market share |

Maintenance and Spare Parts Management

| AI can assist in predicting maintenance requirements and identifying critical spare parts needed for furnace maintenance. By analyzing historical maintenance data and equipment condition, AI can recommend the right quantity and timing of spare parts procurement. | |

| Short-term Benefits | Predictive maintenance and optimized spare parts management reduce unplanned downtime and emergency repairs, leading to cost savings of over 10%. |

| Medium-term Benefits | Extended equipment lifespan and reduced maintenance costs contribute to long-term savings and improved productivity |